|

- Design a conveyor to remove die cast

parts from forming machine and convey parts separately from the plug

into mid level storage bins. Access to the die cast machine

was an important consideration as well as access for maintenance and

die changes.

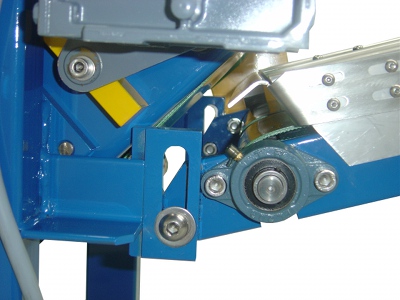

Design a wheel out, low level, inclined

belt conveyor with lugs having central divider to maintain separation

between parts and plugs. One side of the exit system had to

reach over the storage bin of the first, which resulted in the dual

length discharge belts as shown in the photograph. A hinged

checker plate cover was placed over the bottom section so that

operators could safely stand on the unit while attending to issues on

the diecasting machine, without having to first wheel out the conveyor

for access.

|

|

-

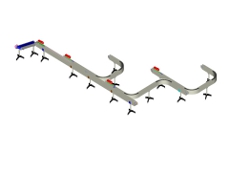

Design and supply a suitable conveyor system

to

take wrapped bars from

two horizontal flow wrappers and optionally merge or keep separate, the

output from these lines. Separate discharge points were

required for each line, or else the combined output was to be fed on to

an inclined conveyor and then on to an AHP supplied vertical

cartoner.

-

Suitable section to allow

products from a third line to be fed into the system.

System of robust, stainless steel constructed, plastic slat conveyors

was designed and merged into an AHP designed inclined belt conveyor for

hand loading into the vertical cartoner.

|

|

AHP has various

designs of general purpose

belt conveyors, inclined as well as horizontal. The conveyors

shown here are transporting filled bags from an AHP supplied vertical

form fill and seal machine to a manual packing station.

|

![Phone: +61 (0)3 9720 8745 Email: enquiries[ at ]authanpack[.]com[.]au](Images/AHP%20LOGO/Contacts.png)