|

-

Identify

physically similar product by the colour of its wrapping which arrives

down a single line conveyor.

-

According

to a selection by the operator, to either

bulk palletise particular colours at any of 5 palletising stations,

inserting slip sheets between layers, or else to pack into corrugated

cartons, seal with hot adhesive, weigh, print and apply label with

product ID, weight and barcode, confirm barcode and bulk completed

carton.

-

Send

packed information to stock handling system for automatic stock

updating. System to operate reliably.

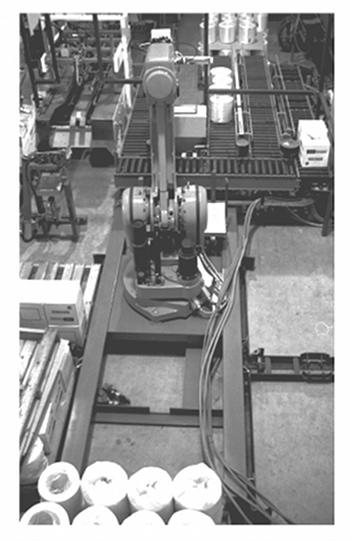

Construct

a robot work cell with robot mounted on slider base to extend its

working envelope.

Cell incorporated 5 pallet stations with selection controls to enable

either bulk palletising

of raw product, or else product packed into cartons. Any

colour/product could be

packed at any of the stations.

Also

incorporated with the robot cell was an AHP designed carton erector

married to a third

party top and bottom case sealer.

|

![Phone: +61 (0)3 9720 8745 Email: enquiries[ at ]authanpack[.]com[.]au](Images/AHP%20LOGO/Contacts.png)