|

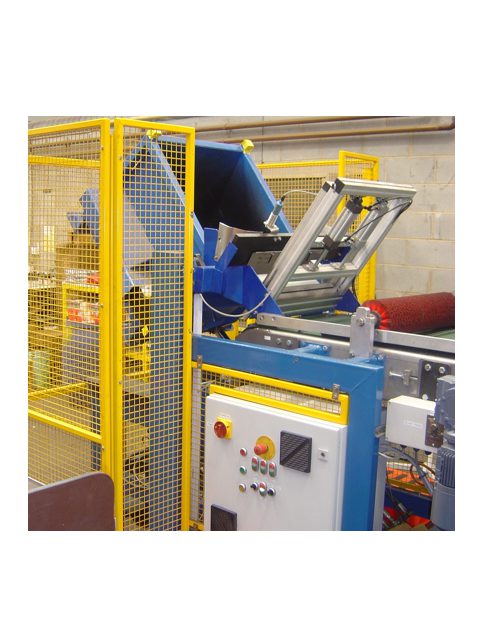

- Automatic

system for emptying bins of car wheel balancing weights,

removing contraries,

weighing into quantities of 100 or 50 (with an accuracy

of ±1product), and bagging and labelling.

- A

pack off system to transfer the sealed bags for manual packing.

- Run products with a large variation in size and

weight, ranging from 10gm

to 70gm.

- Create product bags ranging from 500gm, to 6kg.

A

bin tipping system was designed to meter out balancing weights into a

belt transport system,

and through a series of magnetic and gravitational cleaning systems,

before being

weighed for count. The measured quantity of product is transported

along an elevator

and into a third party vertical form fill seal machine. The film used

is printed on line

with batch and date information, together with pack ID number and

barcode.

This

system

is installed in Victoria, Australia.

|

|

|

AHP

designed and

manufactured die-unloader for the foundry industry. This system was

designed to operate in fairly environmentally harsh conditions, where

it was required to pick-up moulded parts and operate in tandem

with the client's die-moulding machine.

After more than 7 years of continous operation, this system has

recently been expanded to integrate with a new die-moulding

machine the

client has

installed.

|

|

- Automatic machine to orient and deburr

architectural anti slip discs

widely utilised on many surfaces

around Australia.

Product

was oriented and fed single file from a third party vibratory bowl

feeder, and down

a slider. at the bottom of the slide, individual buttons are

presented one at a time to

the rotating deburrer head.

The

system is installed in Victoria, Australia.

Also

constructed for this client was a semi-automatic spot welding system

which positions and welds a stem to the buttons after deburring and

washing. The stem locates the buttons into the mounting substrate.

|

![Phone: +61 (0)3 9720 8745 Email: enquiries[ at ]authanpack[.]com[.]au](Images/AHP%20LOGO/Contacts.png)